Molybdenum Wire: Features, Types, and Uses

Introduction

Molybdenum, a metal known for its high melting point and exceptional strength, has become a key material in various industrial applications. Among the different forms, molybdenum wire stands out due to its unique combination of properties, making it indispensable across multiple industries. This article talks about their characteristics, types, and applications.

Characteristics and Features

Molybdenum wire is prized for several key properties:

- High Melting Point: With a melting point of 2,623°C (4,753°F), it is well-suited for applications that involve extremely high temperatures.

- Strength and Durability: Mo wire maintains its strength even at elevated temperatures, making it ideal for high-stress environments.

- Corrosion Resistance: The wire is resistant to corrosion in many environments, including those that involve acids and other harsh chemicals.

- Excellent Electrical Conductivity: Mo wire is an excellent conductor of electricity, which is why it is often used in electrical and electronic applications.

- Thermal Conductivity: It also has good thermal conductivity, making it effective in applications that require heat dissipation.

These characteristics make Mo wire a versatile material used in a wide range of applications, from high-tech industries to everyday products.

Types and Classification

Molybdenum wire comes in various types, each designed for specific applications:

- Pure Molybdenum Wire: Made from 99.95% pure Mo, this wire is commonly used in high-temperature environments, such as in the production of filaments for incandescent lamps and in the manufacture of heating elements for high-temperature furnaces.

- Doped Molybdenum Wire (TZM Wire): Alloyed with small amounts of titanium, zirconium, and carbon, TZM wire offers improved mechanical properties at high temperatures, making it ideal for use in demanding applications like aerospace components and nuclear reactors.

- Molybdenum-Lanthanum (MoLa) Wire: This wire is alloyed with lanthanum to enhance its ductility and resistance to oxidation, making it suitable for use in electronic devices and thermocouples.

- Spray Molybdenum Wire: Specially designed for thermal spraying, this type of wire is used to apply protective coatings on surfaces, enhancing wear resistance and reducing friction in automotive and industrial components.

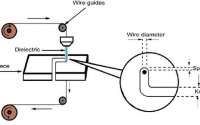

- Fine Molybdenum Wire: Thin Mo wire, often less than 0.01 mm in diameter, is used in precision applications such as wire cutting in semiconductor manufacturing and in the electronics industry.

Applications and Uses

The versatility of molybdenum wire has led to its adoption in numerous industries:

- Lighting Industry: The wire is used as a filament core in incandescent lamps and other lighting products due to its ability to withstand high temperatures without deforming.

- Electronics: Fine molybdenum wire is crucial in semiconductor manufacturing, where it is used in wire cutting and other precision processes. It is also used in cathode assemblies in electron tubes and X-ray tubes.

- Aerospace: In the aerospace industry, the wire is used to manufacture high-temperature components, such as those found in rocket nozzles and jet engines, where strength and thermal stability are critical.

- Medical Industry: Mo wire is used in the medical field for applications like guidewires in minimally invasive surgeries and as a material for radiation shielding in X-ray equipment.

- Furnace Components: The wire is a key material in the production of heating elements and support structures in high-temperature furnaces, especially in vacuum environments where oxidation resistance is important.

- Chemical Industry: Mo wire is used in electrochemical applications, including electrodes in processes that require resistance to corrosion and stable performance over time.

- Automotive Industry: In the automotive sector, Mo wire is used in thermal spraying processes to coat components like piston rings, enhancing their durability and performance.

- Optical and Glass Manufacturing: The wire is used in support grids for optical and glass manufacturing processes, where its high melting point and corrosion resistance are advantageous.

- Energy Sector: It is employed in nuclear reactors for its ability to withstand radiation and high temperatures, as well as in geothermal energy systems where it resists corrosion from high-temperature steam.

- Miscellaneous Applications: It is also used in wire EDM (Electrical Discharge Machining) for precision cutting of hard metals and in the production of high-performance alloys.

Related reading: Types and Uses of Molybdenum Wire

Conclusion

Molybdenum wire is a critical material in modern industry, offering unparalleled performance in applications that demand strength, high-temperature stability, and resistance to corrosion. From the lighting and electronics industries to aerospace and medical fields, it is an essential component in advancing technology and improving product durability.

As industries continue to evolve, the role of Mo wire is likely to expand, further cementing its place as a vital material in the industrial landscape. For more molybdenum products, please check Advanced Refractory Metals (ARM).