Top Uses of Tungsten Carbide

Introduction

Tungsten carbide (WC) is a versatile material with exceptional hardness and durability, making it highly valuable across a wide range of industries.

- Tungsten carbide is known for its exceptional hardness, ranking 8.5 to 9 on the Mohs scale, making it highly resistant to wear.

- With a density of 15.63 g/cm³, it is nearly twice as dense as steel, providing added durability.

- Its high melting point of 2,870°C allows it to perform in extreme temperatures, while a compressive strength of around 7,000 MPa ensures its ability to withstand heavy loads.

- Additionally, its Young’s modulus of 530 to 700 GPa gives it remarkable stiffness, making it ideal for applications requiring strong, long-lasting materials.

Below are some of its top uses:

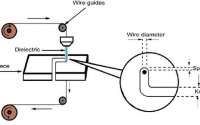

1. Cutting Tools

One of the most common applications of tungsten carbide is in the production of cutting tools. Its extreme hardness makes it ideal for cutting, drilling, and machining tough materials such as steel and other metals. Carbide-tipped cutting tools like saw blades, drill bits, and milling tools provide superior precision, longer tool life, and resistance to wear compared to steel tools.

Related reading: Tungsten Carbide Uses & Properties

2. Mining and Construction

Tungsten carbide plays a crucial role in the mining and construction industries, where equipment faces constant wear and tear. WC is used in drill bits, cutting heads, and other mining tools to increase their lifespan and efficiency. In construction, it is commonly found in heavy-duty machinery components that require high wear resistance, such as road planers and rock-crushing equipment.

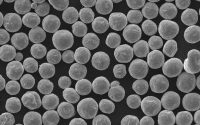

3. Wear-Resistant Parts

Tungsten carbide’s resistance to abrasion makes it ideal for manufacturing wear-resistant parts used in various industrial settings. Valve seats, pump impellers, and nozzles in industries like oil and gas, chemical processing, and food production benefit from the durability of tungsten carbide, reducing maintenance costs and equipment downtime.

4. Jewelry

Though tungsten carbide is primarily known for its industrial uses, it has also found a niche in jewelry manufacturing. Rings, bracelets, and other accessories made from tungsten carbide are highly popular due to their scratch resistance and long-lasting shine. These pieces are valued for their strength and modern, sleek appearance.

5. Sports Equipment

In sports like skiing and hiking, tungsten carbide is used to manufacture tips for ski poles, trekking poles, and crampons. These components need to withstand rugged terrains and high impact, making WC an excellent choice due to its toughness and wear resistance.

6. Military Applications

Tungsten carbide is widely used in military applications due to its ability to withstand extreme conditions. Armor-piercing rounds, for example, are made from tungsten carbide because of its density and hardness, allowing it to penetrate hardened targets.

7. Industrial Machinery

Tungsten carbide’s durability makes it a vital material for manufacturing parts in heavy machinery. Industrial components, including gears, bearings, and wear plates, are commonly made from tungsten carbide to improve the longevity and performance of equipment in harsh environments.

8. Aerospace Industry

The aerospace industry relies on tungsten carbide for producing parts that experience high levels of wear and heat, such as turbine blades, exhaust nozzles, and other engine components. Its ability to maintain strength at high temperatures makes it essential for these high-performance applications.

Conclusion

Tungsten carbide’s exceptional hardness, wear resistance, and high-temperature performance make it indispensable in many industries. From cutting tools and mining equipment to jewelry and military applications, WC continues to be a top choice for products that require durability and long-lasting performance. For more tungsten products, please check Advanced Refractory Metals (ARM).